This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

the problem statement

The solution?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The company

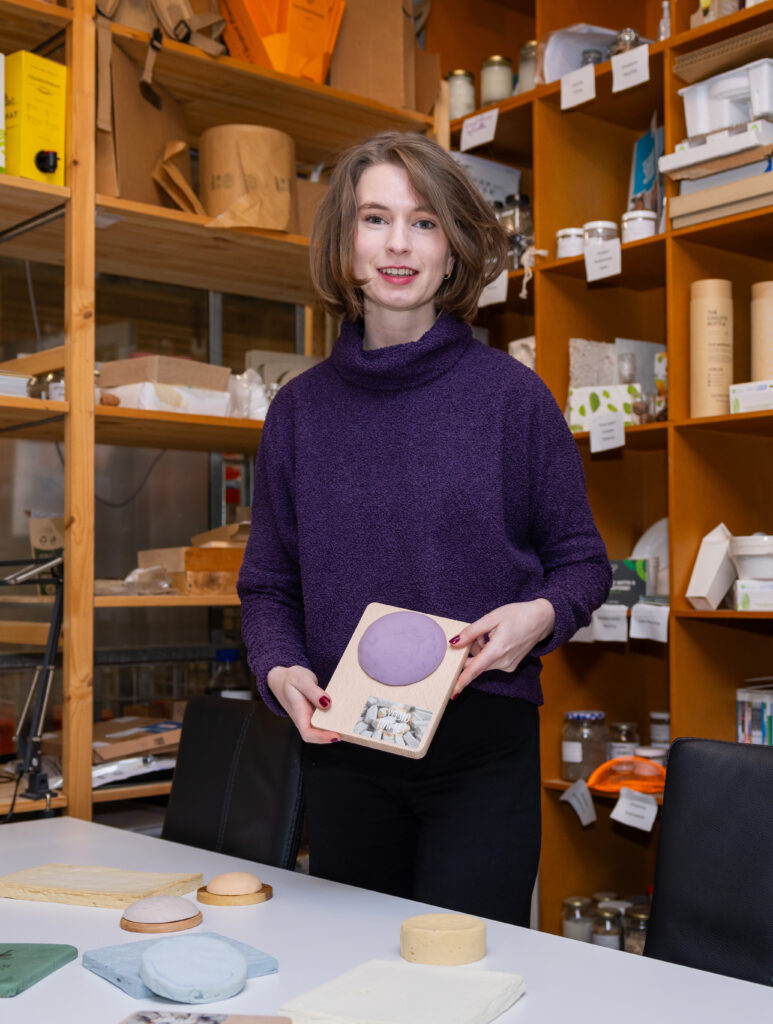

Lisanne Peters is a biomaterial researcher, writer and sustainability advisor based in Arnhem, Netherlands. By blending her background in biomedical sciences and product desig, she forges a path towards a more innovative future. Driven by admiration for biodegradable materials, her work shows an enthusiasm for experimentation, materiality and sustainable impact.

The mission is to shed light on the transformative potential of materials, empoweringthem to shape a better world for all. With her book, SymbioMatter; The Biomaterial Guide, she aims to spread knowledge about how we can make biodegradable materials more widely accessible.

Where creativity meets science

“By Aligning the duration of an object’s existence with the duration of its actual usage, we can reduce the amount of waste generated.”

Lisanne Peters

Founder of SymbioMatter

FAQ's

Material perfomance

SymbioFoam is designed to offer similar performance to conventional PU foams, including cushioning and mechanical stability, depending on the application.

SymbioFoam is mainly intended for non-structural applications such as cushioning or insulation. Use in load-bearing applications depends on the specific formulation and is assessed case by case.

Yes. SymbioFoam is designed to be compatible with existing foam production processes, helping manufacturers adopt it more easily.

Yes. The material can be adapted to meet specific performance and processing requirements for different applications. The material can be adjusted to achieve different densities and levels of stiffness or flexibility, depending on the intended use.

Scalability is a key focus. SymbioFoam is developed with the goal of scaling from pilot to industrial production in collaboration with partners.

Business

Companies can collaborate through pilot projects, joint development, or application testing. We tailor collaborations to shared goals and needs. We actively work with pilot partners and early adopters to test and refine SymbioFoam in real-world applications.

At early stages, costs may differ from conventional PU foams. As production scales, the aim is to reach competitive pricing while offering added environmental value.

Health and safety

SymbioFoam is intended for indoor and consumer applications, subject to appropriate testing and compliance with relevant European standards.

SymbioFoam is developed with end-of-life in mind, aiming for improved circular options compared to conventional PU foams. The exact end-of-life route depends on the application and formulation.